Thermal Storage

Storing heat to augment flexibility for the energy transition.

Heat, when used as an energy vector, is easy to store. This opens the door to a broad range of applications, from bringing flexibility to urban heat networks and increasing the efficiency of industrial processes to smoothing out energy production. It is widely accepted that energy systems are moving toward greater overall efficiency and that this trend will create growing demand for thermal energy storage. Liten is developing a comprehensive range of solutions to address this need.

Liten's thermal energy storage solutions are based on:

An analysis of the energy system in which the thermal energy storage capabilities will be integrated and the expected performance (and constraints): time horizon for energy storage and de-storage, the available and required thermal power for both phases, temperature, available footprint and volume, acceptable equipment costs, etc.

This analysis informs the choice of a thermal energy storage solution (sensible, latent, thermochemical). The chosen solution is accurately dimensioned using simulators at different scales.

Simulation is an iterative process. A simulation is tested in the lab (to validate the fluidics hypotheses), adjusted, and retested.

Next, a demonstrator representative of the actual scale is built so that the entire solution can be validation tested and its functional relevance and overall economic viability confirmed.

The final stage is to support the transfer and implementation of the technology by our partner.

Sensible storage | Latent storage

| Thermochemical storage

|

Low-temperature storage at 80 °C (hot water tank) up to high-temperature storage at 800 °C with ceramic materials. The heat transfer medium used (water, oil, molten salts, air) will depend on the temperatures encountered.

| Storage using phase-change (fusion/solidification) materials.

A wide variety of materials to cover a broad range of temperatures: paraffin with negative temperatures, up to 300 °C with salts; organic materials like sugar alcohol and fatty acids can also be used.

| Use of a reversible chemical reaction that is highly endothermic in one direction and exothermic in the other.

Materials available for different temperatures, from domestic applications (40 °C) to solar power plants (450 °C with quicklime).

Suitable for very long time horizons (inter-season storage).

|

| TRL 6-9 | TRL 4-7 | TRL 2-5 |

Rock-bed thermocline with oil as a heat-transfer fluid (2 MWh for 35 m3).

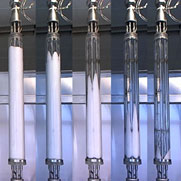

|  Small-scale phenomenological study of the use of solid and liquid paraffin to observe the melt front.

|

Observation of the exothermal nature of the reaction between the quicklime and water spray. (to display full screen click on the icon  ) )

|